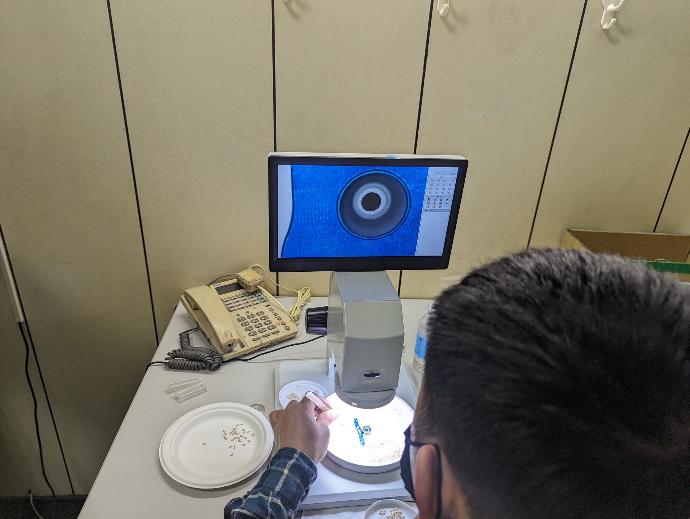

Peek quality control

Where Can PEEK Be Used? Key Industries Benefiting from This High-Performance Material PEEK (Polyether Ether Ketone) is a durable, lightweight, and heat-resistant polymer widely used across various industries due to its exceptional properties. Here’s a quick look at where PEEK makes a difference:

Aerospace

Used for lightweight structural parts, insulation, and high-performance seals that withstand extreme conditions.

Medical

Ideal for implants, surgical tools, and prosthetics thanks to its biocompatibility and sterilization capability.

Automotive

Applied in engine components, transmissions, and electrical connectors to improve durability and reduce weight.

Electronics

Used in insulating parts, connectors, and semiconductor machinery due to its excellent dielectric and thermal resistance.

Oil & Gas

Perfect for seals, valves, and tubing that endure high pressure, temperature, and corrosive environments.

Food Processing

FDA-approved for conveyor belts and machinery parts that require chemical resistance and heat tolerance.Industrial Manufacturing

Common in bearings, gears, and pump components for its wear resistance and strength.

Why Choose PEEK?

•High temperature and chemical resistance

•Lightweight yet strong

•Biocompatible and durable

PEEK is a versatile material that enhances performance and longevity across demanding applications.

Interested in using PEEK for your project? Contact us today!

2022 / 9 / 02