Espresso coffee tamping station

How We Manufacture a High-End Tamping Station

At first glance, a tamping station might look like a simple accessory—but crafting a premium one is a serious job. Most high-end tamping stations are made from stainless steel, and for good reason: it's durable, corrosion-resistant, and has the right aesthetic for specialty coffee gear. But not all stainless steel is created equal.

We typically use high-grade stainless steel with low carbon content. You may have heard of 400 series stainless steels like 420 or 430—these are known to rust over time due to their higher carbon levels. For our tamping stations, we choose grades that resist rust even in humid environments, ensuring long-term reliability and clean looks.

Step-by-Step Manufacturing Process

1 Material Selection & Laser Cutting

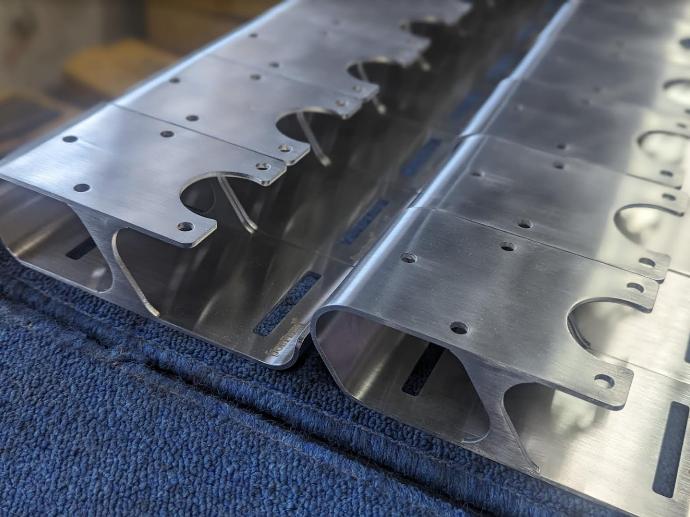

We begin with brushed stainless steel sheets in the correct thickness. The brushed finish gives it that sleek, matte look from the start. Using a laser cutter, we shape the outer profile with precision.

2 Forming the Body

Next comes forming. We design and create custom rollers and forming dies to achieve the desired curves and angles. This stage defines the ergonomic shape of the tamping station.

3 Laser Welding the Side Walls

Once the part is formed, we laser weld the side walls. This ensures strength and a seamless appearance. It’s critical that the welds are clean and consistent.

4 Grinding and Brushing

After welding, we grind down the weld lines. Then we re-brush the surface to restore the uniform finish and remove any signs of the welding process. This also eliminates sharp edges that could pose a risk to users—an especially important point. No sharp edges are allowed on this product. Safety and comfort come first.

5 Hand-Finishing the Inner Edges

While our brushing machines take care of most surfaces, they can’t reach inside

corners and edges. For those, we use 200-grit sandpaper by hand to smooth and round them out. Every piece is handled individually to ensure consistent quality.

A Labor of Love (and Experience)

This is a time-consuming process, but it’s what it takes to create a high-end stainless steel product. Achieving perfection is not easy it requires years of experience, attention to detail, and a relentless pursuit of excellence. We are still chasing that perfection, one piece at a time.